Laser cutting

Laser cutting technology is characterized by a heat cutting process in which the energy of the combined laser beam is used to achieve high speed and high cutting precision with the least possible heat affection of the surface.

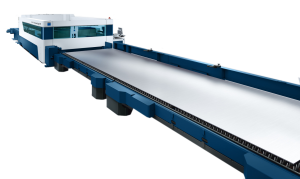

TRULASER 8000

The TruLaser 8000 laser cutting machine provides the highest cost efficiency and outstanding part quality in oversize sheet format processing.

|

Performance

|

6 kW

|

| Table and sheet max. dimension |

2 500 x 8 000 mm

|

|

Max. sheet thickness for cutting:

|

|

|

Mild steel

|

25 mm

|

|

Stainless steel

|

25 mm

|

|

Aluminium

|

15 mm

|

TruLaser 3060 Fiber (6KW)

High performance laser machine Trumpf TruLaser 3060 Fiber is using the True disk laser source for generating the beam. Together with the brightline technology, it enables to achieve great surface quality and tolerances with little surface heat affection.

|

Performance

|

6 kW

|

| Table parameters |

2 500 x 6 000 mm

|

|

Max. sheet thickness appropriate for cutting:

|

|

|

Mild steel

|

20 mm

|

| Stainless steel |

20mm

|

|

Aluminium

|

16 mm

|

Laser BYSTRONIC Bystar 4020 a 4025

|

Performance

|

4,4 kW

|

| Table parameters |

2 000 x 4 000 mm(Bystar 4020) 2 500 x 8 000 mm(Bystar 4025) |

|

Max sheet thickness appropriate for cutting

|

|

|

Mild steel

|

20 mm

|

|

Stainless steel

|

15 mm

|

|

Aluminium

|

12 mm

|

|

Rotary axis:

|

|

|

Hollow sections diameters

|

15 – 315 mm

|

|

Maximal beam lenght for processing of 1 part

|

3700 mm

|

High performance cutting machines BYSTAR 4025 and BYSTAR 4020 are used for high precision cutting with little surface heat affection. There is a possibility of cutting small holes into thick sheet with technology of pulse cutting. The BYSTAR 4020 has an Integrated CNC rotation axis for tubes and hollow section cutting with a pneumatic chuck installed directly in the frame.

Material grade requirements:

The parts produced from recommended laser material (RAEX) show in thickness over 6mm an optimal cutting quality and guarantee dimension tolerances according STN EN ISO 9013 I A.

The basic material is specified and marked within the drawing documentation which is archived. Therefore, it is additionally possible to reprint a material certificate for the specified pieces.

General conditions

- The material quality is determined in the customers drawings and upon request. It is possible to provide a material certificate for any part.

- It is possible to arrange painting or sandblasting of the parts. If the parts are according to the drawing specifications processed for bending, the parts will always be sandblasted.

- The parts are delivered with a rough surface according to EN 10 163.

- Shape dimension tolerances of parts are delivered according EN 10029.

- Cut surface quality is assured according STN EN ISO 9013 grade II. Local surface defects are not taken into consideration.

- The standard delivery time, when the material is available on stock, is from 3 to 10 labour days, after the order confirmation.

- Express delivery orders are possible upon request and extra charge. The delivery parity is EXW or, otherwise when agreed upon. PMR, s.ro. has the possibility to arrange transport upon request.