3D Plasma Cutting

The technology of plasma cutting uses a concentrated electric arc that melts the material through the effect of a high-temperature plasma beam. All conductive materials can be cut.

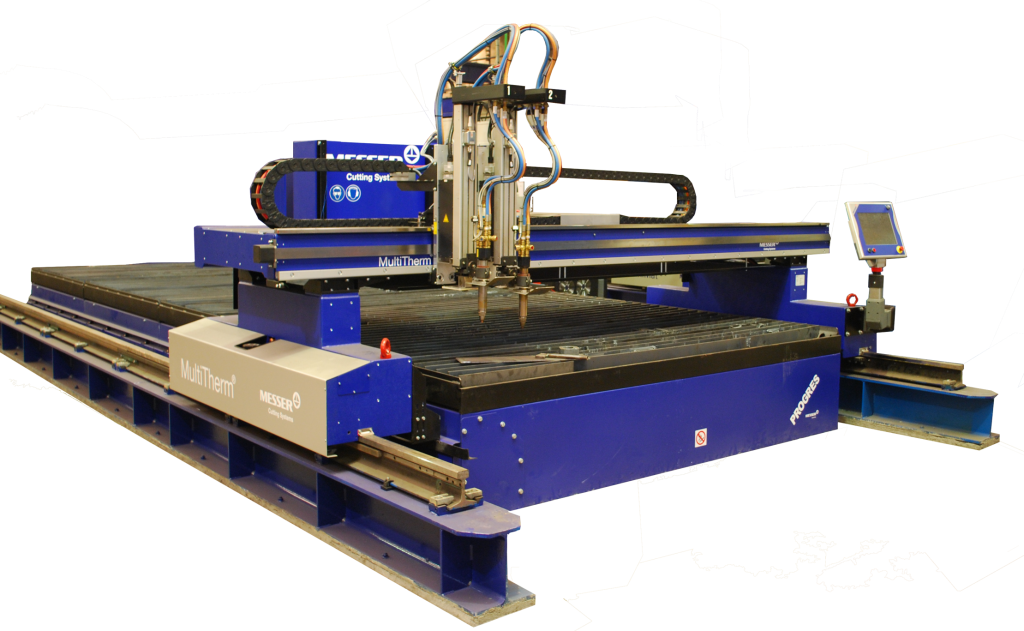

We use a machine equipped with an endless rotator generating the plasma flow in the place of the surface we want to cut. The difference is, that the rotator can tilt up to 45⁰ to any side.

The robust gantry allows us to reduce the vibrations during operating the machine to a minimum. The compact and powerful design ensures high precision and dynamics that allows us to cut complex bevel contours, thus saving time and handling.

Using plasma cutting, the penetrated surface is less disrupted than by using oxygen, but it is necessary to take into consideration a cut surface angle deformation of about 5⁰.

|

Max. size:

|

2,5 x 8m

|

| Max. thickness: |

50mm

|

| Max. head tilt: |

+-45°

|

General conditions

- The material quality is determined in the customers drawings and upon request. It is possible to provide a material certificate for any part.

- It is possible to arrange painting or sandblasting of the parts. If the parts are according to the drawing specifications processed for bending, the parts will always be sandblasted.

- The parts are delivered with a rough surface according to EN 10 163.

- Shape dimension tolerances of parts are delivered according EN 10029.

- Cut surface quality is assured according STN EN ISO 9013 grade II. Local surface defects are not taken into consideration.

- The standard delivery time, when the material is available on stock, is from 3 to 10 labour days, after the order confirmation.

- Express delivery orders are possible upon request and extra charge. The delivery parity is EXW or, otherwise when agreed upon. PMR, s.ro. has the possibility to arrange transport upon request.